Products

Continuous Hot Rolled Galvanized Sheet Production Line (HGI)

Classification Solution

Hot-rolled plate is used as raw material, and the surface of strip steel is covered with a layer of zinc or aluminum-zinc alloy by hot-dip coating. It has strong cathodic protection performance, making it widely used in various fields such as industry, agriculture and construction. Today's widely used coating products.

- Overview

- Inquiry

- Related Products

Main features of the unit:

Raw material: Strip width: 600-1550mm, thickness: 1.5-4.0mm, hot-rolled low carbon steel coil after pickling, no oil or less oil.

Plating type: GI, GA, GF; weight: 60-600g/m2

Product quality: In line with GB/T2518-2008

Unit speed: Inlet Max200mpm, process section, Max150mpm, outlet section Max200mpm

Annual output: 200,000-400,000tpy

Energy-saving method: Waste heat recovery of exhaust gas, SUNNY patent

Continuous annealing furnace: Non-oxidizing heating (NOF) + radiant tube heating (RTF), horizontal or L type

Fuel type: Natural gas, liquefied petroleum gas, mixed gas, coke oven gas

Welding equipment: Double rolling lap seam welder

Degreasing form: Chemical degreasing + electrolytic degreasing + tertiary water rinsing, horizontal (can be omitted)

Zinc pot type: Ceramic induction zinc pot

Air knife: SUNNY patent

Finishing machine: Four-roll wet finishing, large rolling force of 6,000KN

Pull straightening machine: Two bends and one straightening

passivation/fingerprint resistance: Cr6+, Cr3+, inorganic passivation, roller coating

Oiling method: Electrostatic oiling

Electrical control system: SIEMENS or ABB AC frequency conversion control system

Industrial automation: SIEMENS or ABB automation control system

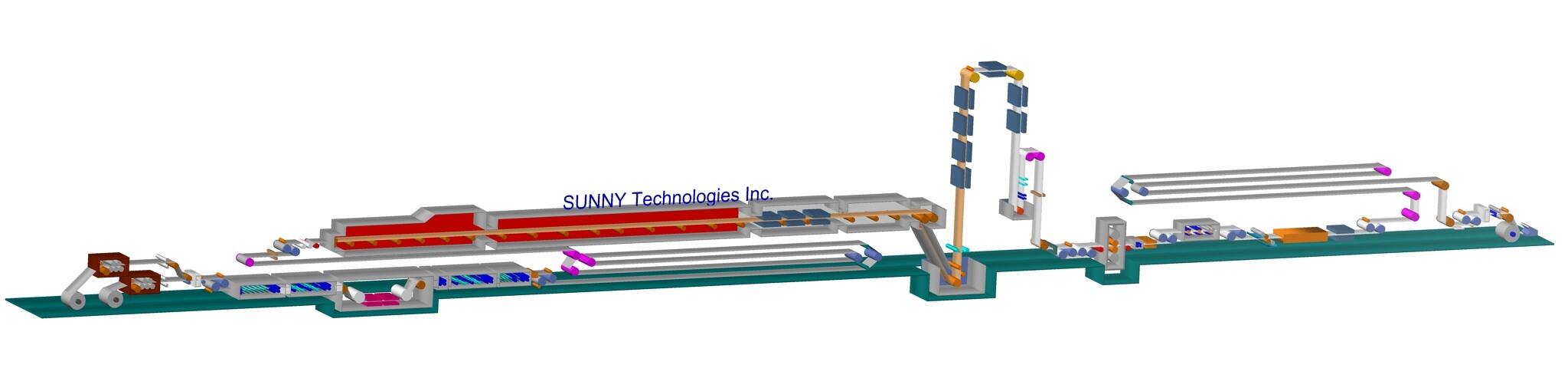

The main process flow of the unit:

Uncoiling→welding→degreasing (optional)→NOF reduction →galvanizing→(alloying)→smoothing→straightening→passivation/fingerprint resistance→electrostatic oiling→slitting→coiling

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY