Products

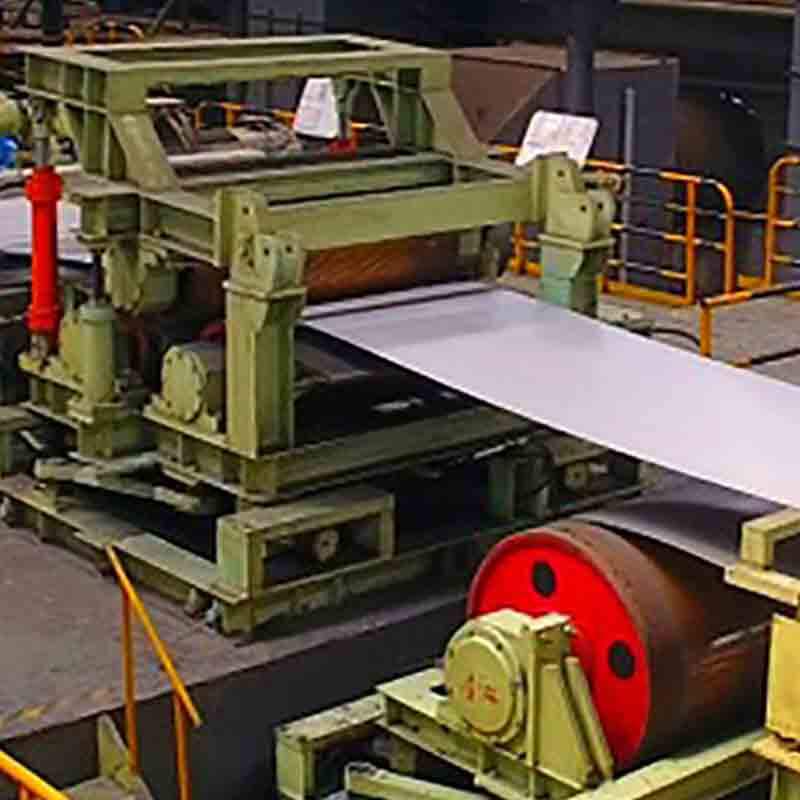

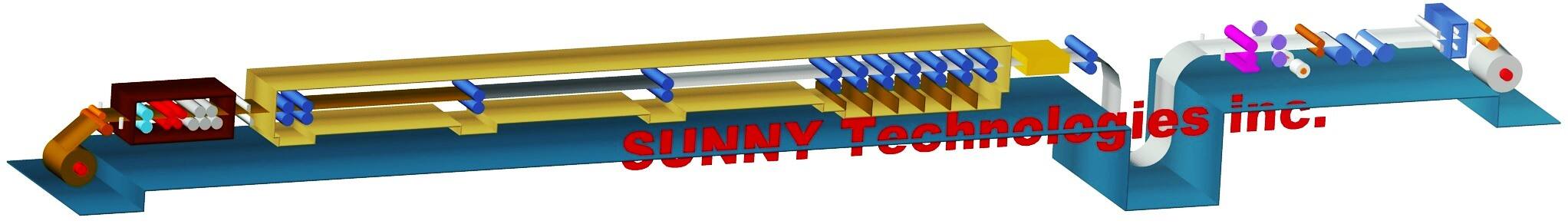

Carbon steel push-pull pickling unit (PPPL)

Classification Solution

The push-pull hydrochloric acid shallow groove turbulent pickling process is used to remove the iron oxide layer on the surface of the hot-rolled steel strip and cut off the irregular edges of the steel strip to provide qualified hot-rolled plate raw materials for the next process. The steel strip after pickling has a pure iron surface and can be cold rolled or hot-dipped galvanized.

- Overview

- Inquiry

- Related Products

The push-pull hydrochloric acid shallow groove turbulent pickling process is used to remove the iron oxide layer on the surface of the hot-rolled steel strip and cut off the irregular edges of the steel strip to provide qualified hot-rolled plate raw materials for the next process. The steel strip after pickling has a pure iron surface and can be cold rolled or hot-dipped galvanized.

Unit characteristics

Using single unwinding non-continuous type; using hydrochloric acid multi-stage shallow groove turbulent pickling process and multi-stage water rinsing process

Annual production scale: 200,000-600,000t/a

Raw material: Carbon steel hot rolled coil

Steel grade: CQ, DQ, DDQ, IF, HSLA, W440-W1300 silicon steel

Raw material specifications: 1.5-6.0mmx width: 650-1650mm

Roll diameter: I.D.Φ760/Φ610mmO.D.MaxΦ2150mm Maximum roll weight: 30t

Hot rolled coiling temperature: Max670 degrees (IF<720 degrees)

Threading speed: 30-60mpm

Process speed: Max150mpm

Pickling time: 25-30sec

adopt SIEMENS or ABB electrical control system

Production process

Coiling→uncoiling→straightening→head cutting→corner cutting→HCL pickling-water cleaning-drying→trimming→inspection→tail trimming→oiling→coiling→unwinding

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY