SUNNY feliciter lineam transformationis Zhengshan Zhongsheng Electric Steel perfectam esse in 236 diebus

SUNNY Co., Ltd. laboravit per 236 dies et complevit

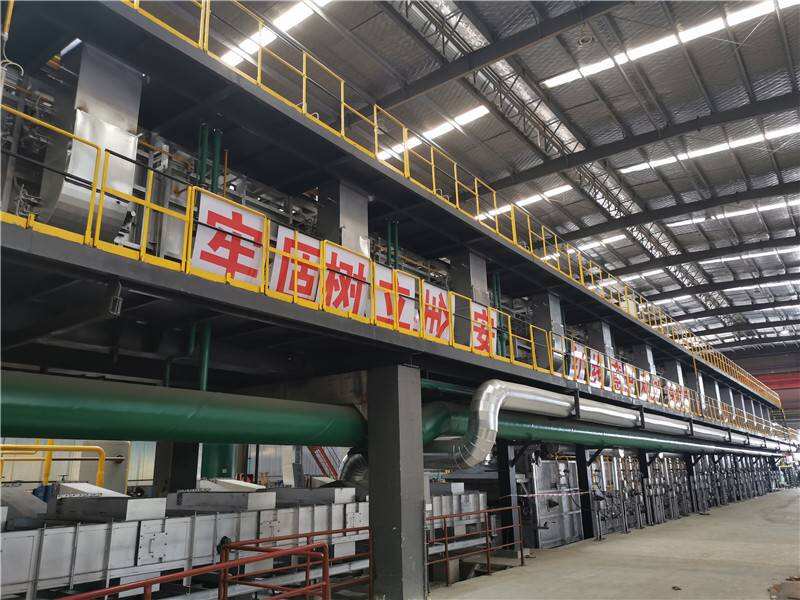

Zhongshan Zhongsheng Electric Steel Transformation Line

Die IX kalendas Maias, anno DOMINI 2021, SUNNY Technology Co., Ltd. suscepit originalem lineam processus aceris inox a Zhongshan Zhongsheng Metal Strip Technology Co., Ltd. in civitate Zhongshan, provincia Guangdong. Cum coniunctis industriis utriusque partium, superatis difficultatibus causatis ab epidemia, in 236 diebus feliciter transmutata est in continuam unitatem decarburizationis et recalentis cum revestimento (unitas III) pro productione aceris electrici non directi, et primum volumen productorum aceris electrici qualificatorum officialiter de linea recessit per unitatem III.

In August 2020, Zhongshan Zhongsheng Metal Strip Technology Co., Ltd. (henceforth referred to as Zhongshan Zhongsheng) in Zhongshan City, Guangdong Province, after observing the pandemic, noticed that the market gradually improved, especially the market changes and skyrocketing demand in the second half of the year. In order to seize this rare market demand opportunity, it was planned to decide on the strategic transformation of the company and convert the original stainless steel processing line. An agreement was signed with Huangshi Shanli Technology Co., Ltd. (hereinafter referred to as: Shanli Company), the first post-pandemic contract. Through the transformation contract, and by means of the transformation, it will be able to produce low- and medium-grade non-oriented electrical steel. The cold-rolled non-oriented electrical steel strip is degreased on the surface of the strip, and recrystallized and annealed in a protective atmosphere to grow the grains. The magnetic level is improved, stress is eliminated, and the function of an insulating layer is applied. Its designed maximum processing capacity is 250,000 tons/year. The raw material variety is non-oriented electrical steel (50W470-50W1000), and the specification is 800mm-1250mm×0.35mm-0.65mm, with a remote maintenance platform, front and rear double tension straightening arrangement, and a design unit process speed of Max. 135m/min.

Postquam Societas Shanli, ut societas ingenii metallurgici professionis domesticae, suscepit proiectum, sub conditionibus temporis contracti angusti, gravium laborum et difficultatis epidemiae, omnes departmenta societatis simul operata sunt ad planos correspondentes constituendos et omnes operarii ad progressum festinaverunt. Ut tempus constructionis non differretur, in mense Ianuario anno 2021, Societas Shanli mittet omnia instrumenta ad locum ut incommoda transportationis post annum novum dum Festivitas Primaverae sit evitentur et constructionem non impendant. Post Festivitatem Primaverae die XVIII Februarii (septima die mensis), omnes operarii constructionis intrabunt locum ad initium constructionis et installationis instrumentorum. Cum fundamentum loci et facilitates auxiliares nondum plene parata sint, opera praecedentia quantum potest agantur, et tandem die XV Aprilis anno 2021 incipiant. Ingressi stadium probandi, tempus probandi est triginta dies, et productionem incipere praeparatum est ad diem XV Maii.

Successus huius lineae transformationis demonstrat plene "Velocitatem Virium Montium". Est etiam exemplificatio cooperationis equipae principalis et variarum departmentorum societatis Shanli ad servandum diligenter Zhongshan Zhongsheng.

EN

EN

AR

AR

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

ID

ID

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

BE

BE

UR

UR

BN

BN

JW

JW

LA

LA

MI

MI

MN

MN

NE

NE

PA

PA

KK

KK

TG

TG

UZ

UZ

KY

KY